Laser marking is one of the most reliable, versatile and cost-efficient product marking methods available.

The technology is perfect for high volumes of printing and creating easy traceability on food, drink and pharmaceutical products. A concentrated beam of light is deflected by mirrors through a lens to form characters by removing material or coating from the product or packaging. Accuracy is guaranteed, giving you 24/7 operation without the need for users to manually intervene.

Laser marking permanently changes the surface of the substrate. For example, when coding onto painted card, the very top layers of paint are removed revealing the contrasting bare card underneath. The same process on plastic changes the very chemical nature of the material, either melting it to leave a mark or causing a colour change. When coding on glass, the laser leaves micro cracks, scribing a permanent code without weakening the material.

Linx Fibre lasers can permanently mark on a wide range of materials, including metal, rubber, plastic, and packaging foils.The very fine spot size creates excellent quality codes and makes Linx Fibre lasers ideal for marking very small components, or large amounts of information onto small areas.

CO2 laser coders can be used to code and mark almost every kind of surface, from glass to plastic to coated metals, across every kind of industry even on high speed production lines.

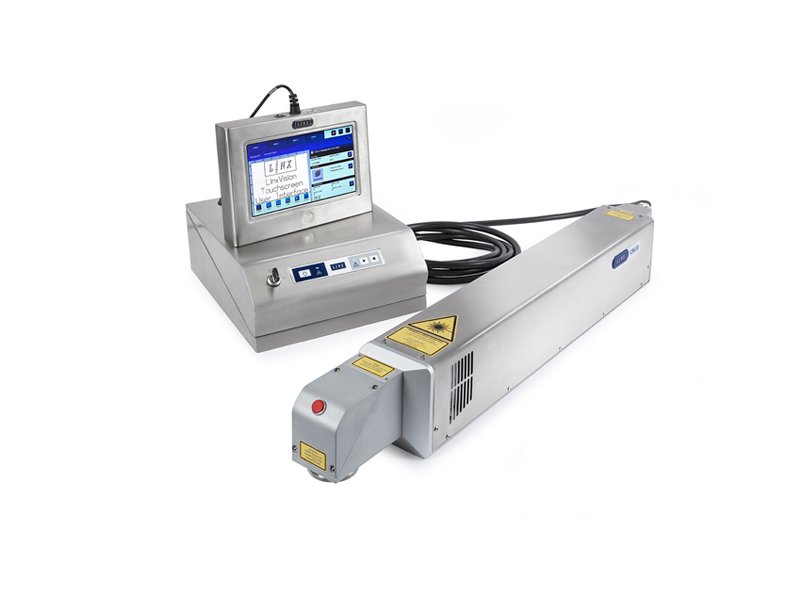

The Linx CSL10 is a high specification, 10 W CO2 scribing laser coder. Designed to be economical yet versatile, it is suitable for a wide range of laser marking applications. Produces complex variable codes and dynamic messages, even on high speed lines for quality coding on a wide range of materials.

Read More

The Linx CSL30 laser coder produces sharp codes on fast lines, and even on hard to mark materials such as glass and rubber. It’s been designed to keep up with your coding requirements as they change – line speed, code complexity, or material types – with no any additional investment needed in it.

Read More

The Linx CSL60 Laser System marks complex codes at a high resolution onto high-speed lines. The 60 W laser power combined with a powerful processor allows coding onto hard to mark materials such as glass and rubber. Full system IP65 rating makes it a reliable coding solution for harsh production environments such as beverage, automotive or extrusion.

Read More

Permanently mark on a wide range of materials, including metal, rubber, plastic, and packaging foils. Very fine spot size creates excellent quality codes and makes Linx Fibre lasers ideal for marking very small components, or large amounts of information onto small areas. Text, machine readable codes, graphics and logos are all marked with extreme clarity for traceability..

Read More

Linx SL3 Laser Coder 30W compact and robust laser coder The Linx SL3 Laser Coder is affordable, enabled by a single laser coding unit with flexible configurations to meet your needs. Simple to install and easy to maintain, the Linx SL3 provides an ideal marking solution onto a wide range of products. With its IP54.

Read More